our logistic solutions

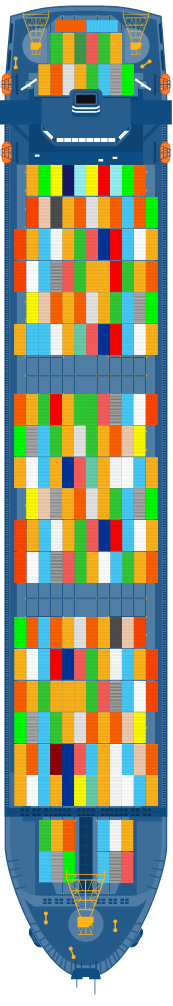

At Tampa Metal, our logistics operations are the backbone of our recycling process. With our dedicated port located in Tampa, we have a strategic advantage that allows us to streamline the transportation of scrap metals directly to our facility. Our port is equipped to receive large volumes of scrap metal shipments, and thanks to our integrated rail access, trains can deliver materials straight to our port, ensuring seamless and efficient logistics.

Our logistics team coordinates every step of the supply chain—from the timely arrival of trains carrying scrap materials to their efficient unloading and processing at our state-of-the-art facility. This direct access to the port and rail network enables us to reduce transit times, minimize delays, and optimize the flow of materials to meet client demands.

Efficient Transport Coordination

Coordinating the timely arrival and departure of trains to ensure continuous flow of scrap materials is essential. Proper scheduling helps prevent delays and ensures that scrap is delivered to the facility for processing as quickly as possible.

Port Operations Management

Since the port serves as a critical hub for receiving large scrap shipments, managing port operations efficiently—such as unloading trains, sorting materials, and dispatching them to the recycling plant—is vital for operational success.

Inventory Management

With high volumes of scrap coming in via train, Tampa Metal needs to maintain precise inventory control. This ensures the company knows what materials are available and can optimize sorting and recycling efforts without backlogs.

Environmental Compliance and Safety

Handling large volumes of scrap at a port requires strict adherence to safety and environmental regulations. Tampa Metal must ensure that all activities, from unloading to transporting the scrap from the port to the recycling facility, comply with local, state, and federal regulations.

Cost Management

Transportation costs, both by train and internal handling at the port, are significant factors. Optimizing these logistics processes helps Tampa Metal maintain competitive pricing in the scrap metal market while ensuring profitability.

Real-Time Tracking and Communication

Implementing real-time tracking systems for incoming scrap shipments via train allows Tampa Metal to monitor the progress of deliveries and adjust operations as needed. Effective communication between the port, rail operators, and recycling facility ensures that any delays or issues are quickly addressed, maintaining smooth operations and minimizing downtime.

We utilize real-time tracking systems to monitor shipments and ensure smooth operations. Safety, environmental compliance, and cost-effectiveness are at the core of our logistics strategy, ensuring that we handle every shipment with care and precision.

Tampa Metal’s logistics capabilities guarantee reliable service, efficient operations, and a commitment to sustainability, making us a trusted partner in the recycling industry.